Calendering is the forming of a thermoplastic mass between two or more rollers into a foil.

Calendering is the forming of a thermoplastic mass between two or more rollers into a foil.

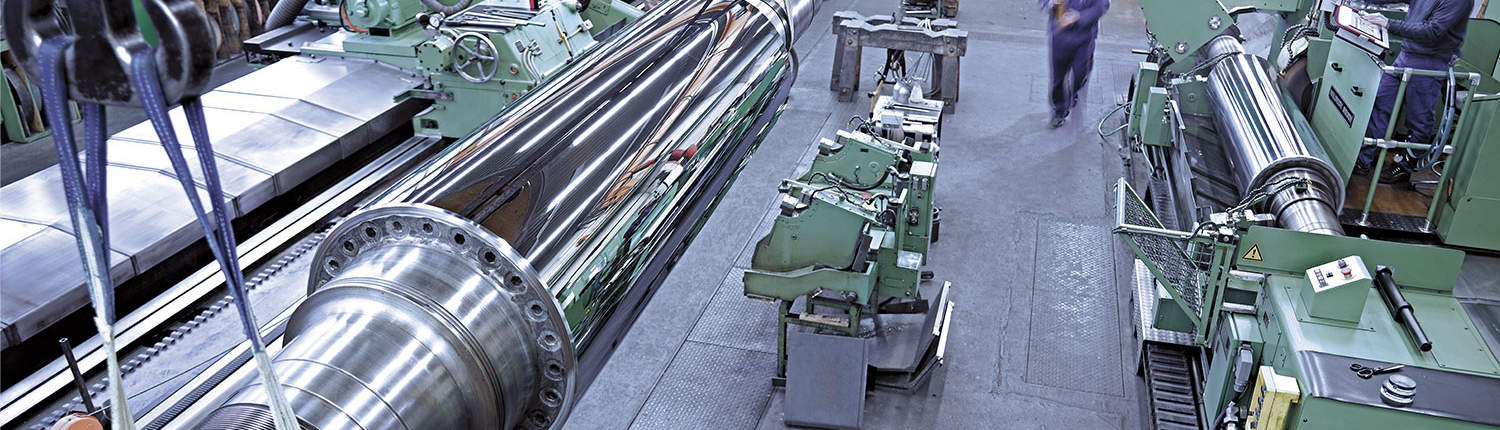

Calendering is an industrial technique. It involves heating and kneading a plastic thermoplastic mass into a viscous form and then processing it between two or more rollers into a cooled foil or strip of a certain thickness. The strip or foil obtained can be either the end product or a semi-finished product.

Calender rolls are used for the production of plastic foil and rubber products. With Calender rollers, even the smallest defects in the roll surface, e.g. pores or cracks, have to be excluded to ensure the best possible quality of the product. The more precise the grinding of the Calender rolls, the better the product tolerance value.