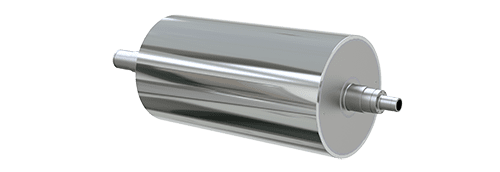

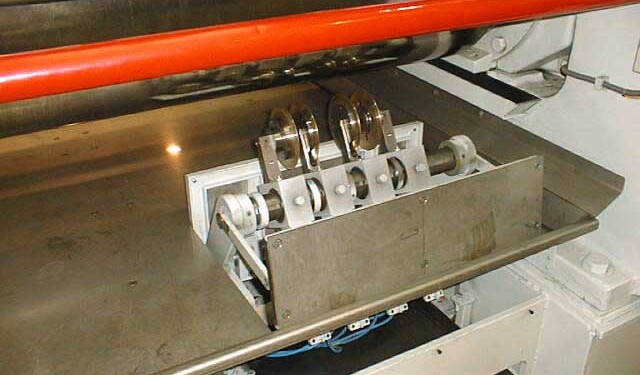

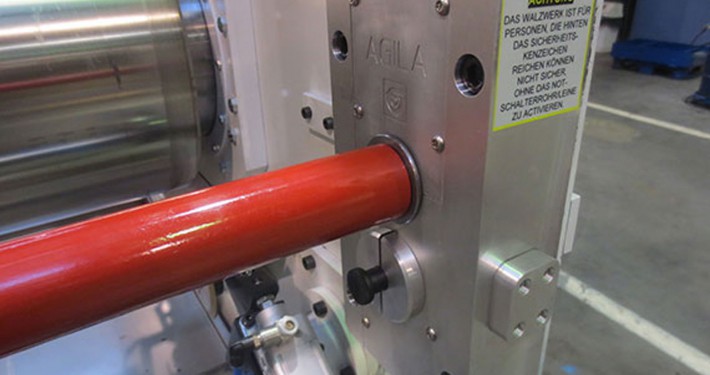

Today’s world is inconceivable without caoutchuc, rubber and plastics. They can be found in almost all products in everyday life. Car tires, plastic films, seals or drinking cups are typical products of the rubber / caoutchouc and plastics industries. Mixing rolls, calender rolls, heating / cooling and smoothing rolls are used to manufacture many rubber and plastic products in machines and systems around the world.